WET SETTING

CHECK OUT OUR COVER STORY IN GAS COMPRESSION MAGAZINE!

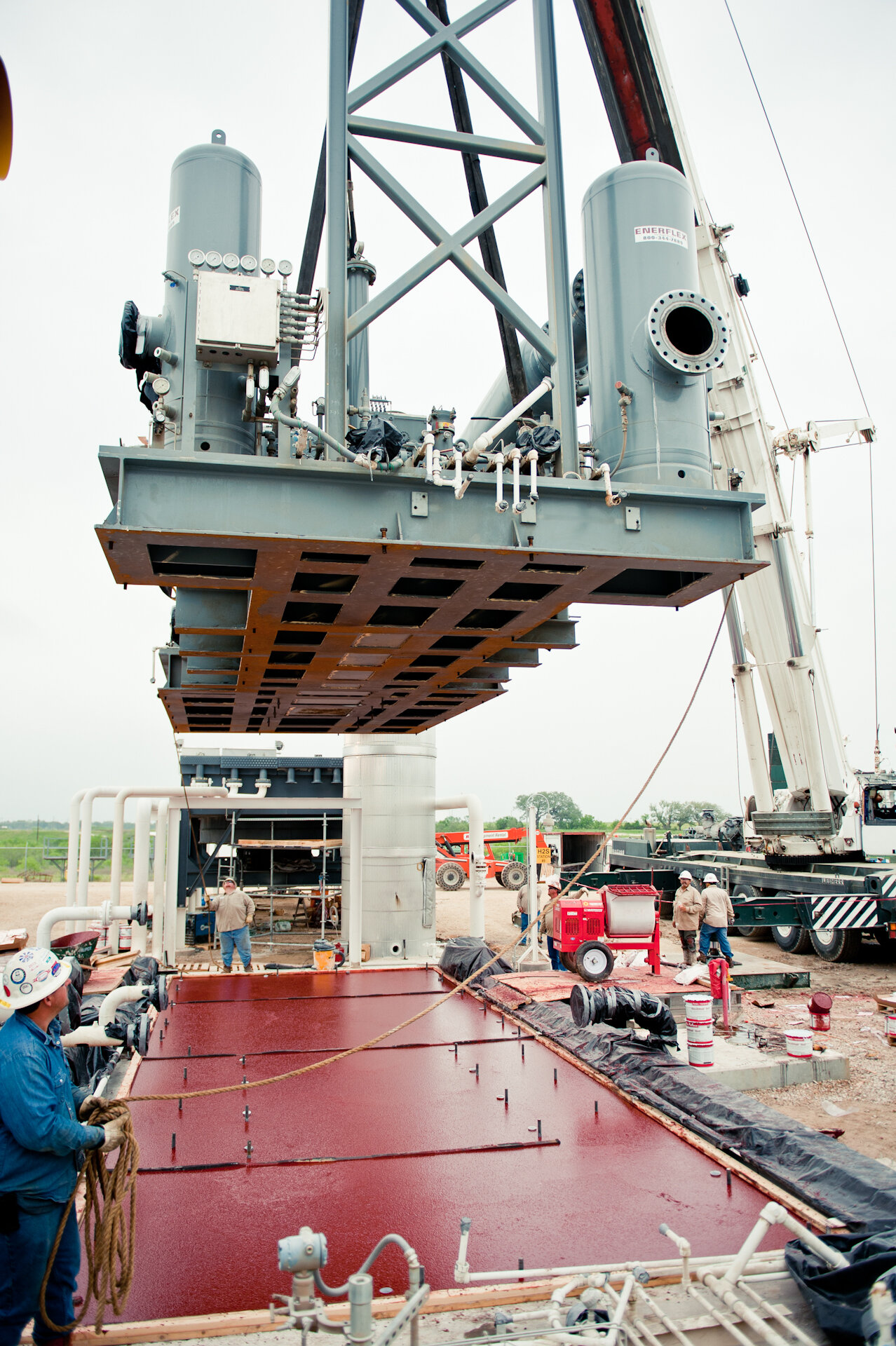

With this type of grouting, utilizing an epoxy grout with over 120-minute pot life at 70°F is necessary. Additionally, incorporating Bill Spitzer & Associates field matter experts with wet setting is required for this unique and specialized service. We project manage this procedure, guide the pouring of epoxy grout onto a foundation, and then supervise the crane lowering the equipment into the predetermined aligned location. This process is critical where the equipment has minimal access through the equipment to properly place grout. Typical applications are lube oil skids, pumps with negligible entrance, and large sole plates.

Our goal is to provide this grouting solution service to deliver full contact or effective bearing area (EBA) for critically aligned rotating equipment. Here is how we achieve that:

"BEFORE"

Technical and Engineering Data Analyzation

With over 100 years of collective experience, we have seen just about every problem, configuration, and circumstance. The technical expertise of our personnel is perhaps our largest advantage for our customers. Bill Spitzer & Associates salespeople review baseplate, bedplate, soleplate, anchor bolts, concrete foundation, lubrication, and oil mist designs of critical equipment.

Ensure Constructability

Collaborate with construction group and owners on the installation plan procedure

Based on epoxy grout, site obstacles, critical equipment, foundation, and other variables

Review the site and visually examine perimeter, construction prep, and foundation formwork

Advise of proper expansion joint locations

Review APA 686, ACI 351, & PIP STS03601 specification checklists

Calculate the volume of pour and manpower

Arrange all key players and schedules for pouring time and date

Situational weather condition planning

"DURING"

On-Site Technical Grouting Supervision and Guidance

Pre-meeting with owners, contractors, OEM’s that affect the installation

Review of scope procedures and implement necessary changes

Verify procedures and changes are correct

Recalculation of epoxy grout materials

Assessment of manpower installation equipment

Discussion of potential weather variables and adaptable plans

Identification of any site constraints or obstacles

Inspection of foundation and formwork

Examination of proper expansion joints

Reassure jack bolts and leveling pads remain fixed to assure alignment

Confirm anchor bolts are protected and isolated

Prevention of the job from starting with identified issues

Instruction of proper mixing, placing, and pouring

In accordance to manufacturers technical data sheet and industry standards

Use of recommending tools and components

Supervision of grout sequencing

Confirm 100% epoxy grout beam, skid, baseplate, or equipment contact

Education of proper clean up and disposal methods

"AFTER"

Communication

Provide theoretical cure times

Assist with other aspects needed to provide project satisfaction