INDUSTRIAL IN-PLANT

Overview

The variety of Industrial in-plant lubrication applications are as varied as is the equipment available to accomplish the task. Drip oilers, oil cans, and hand operated grease guns are disappearing; and so are the maintenance personnel to perform these routine jobs. With leaner operations comes the need to automate as much of the lubrication process as possible, which frees up severely limited manpower.

Key Components

Lubrication pumps offer the greatest variety among lube system components

Pumps get the lubricant supply from original pails, kegs, drums, or multiple sizes of self-contained reservoirs

Hand, Air, AC/DC or hydraulic operated pumps

Built-in: controllers, feedback monitoring, pressure switches/transducers, low level sensors

Single Stroke, reciprocating, and rotary driven - for the widest range of lubricant delivery

Single and multi-point lubricators with built in timers, pre-filled or fillable reservoirs

Metering Devices

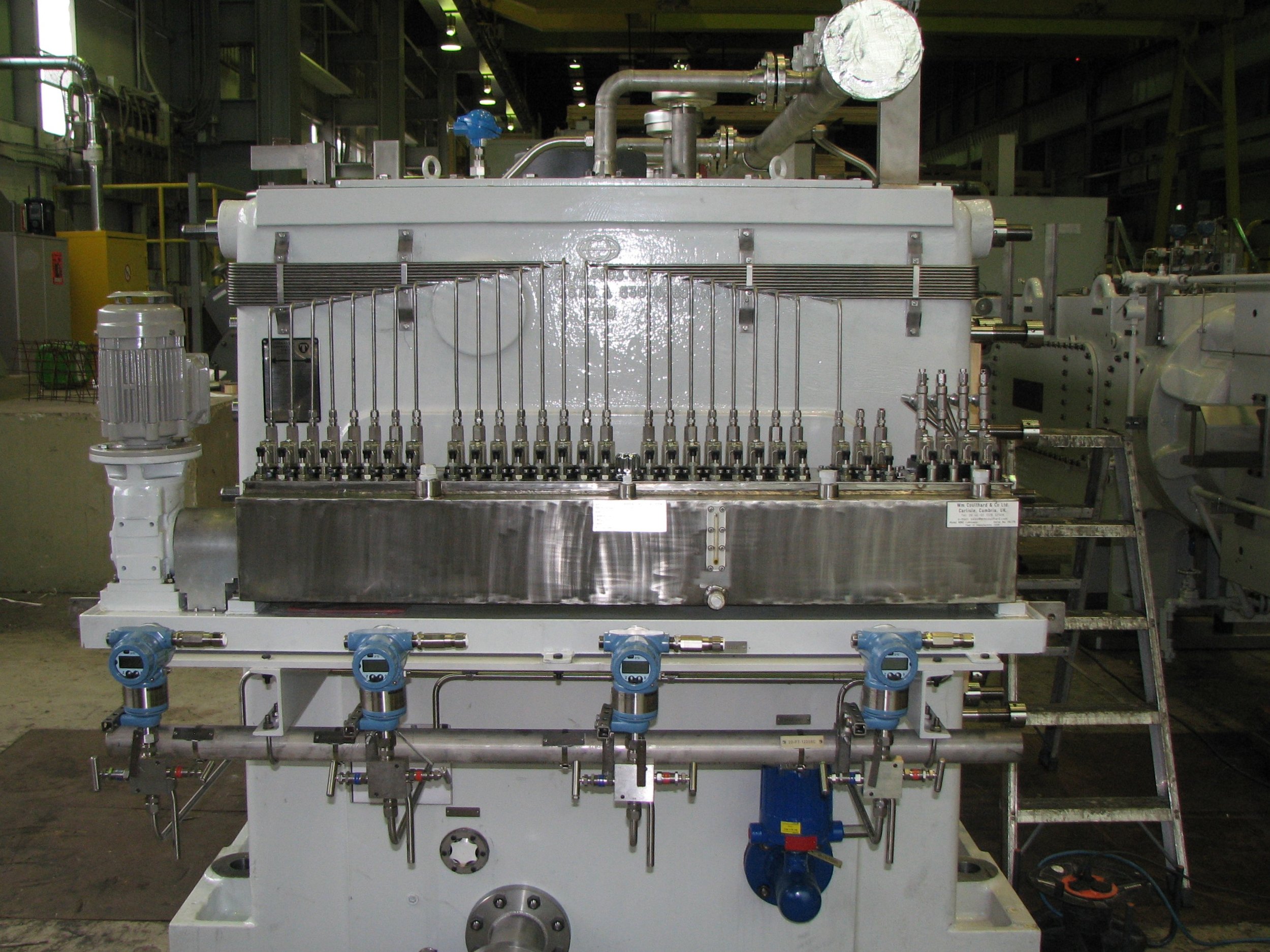

Positive displacement divider blocks – modular/segmented or traditional style; single-line progressive or dual line; carbon steel or stainless steel construction

Single-line injectors – wide range of lubricant displacement; multiple size injectors used in the same circuit; carbon steel or stainless steel construction

Value

Optimized oil consumption & minimized effects of lubricant downstream

Design, manufacturing, testing, installation and maintenance expertise

Quality components means repeatable performance and long service life

Examples

Natural Gas compressors – separable and integral machines in Natural Gas Production & Transmission

Process gas compressors in Petro-Chemical Plants & Refineries

Fuel gas compressors feeding gas turbines

Air compressors in Heavy Manufacturing Facilities