Automatic Lubrication System - Simple and Efficient

At BSA, we specialize in the design and manufacturing of advanced control panels for automated lubrication systems, tailored to meet the specific needs of the client in various industries. Whether new lubrication systems, or existing, BSA is focused on precision, reliability, and innovation, of our control panels to ensure that lubrication systems operate smoothly, efficiently, and with minimal human intervention.

Key Features of Our Control Panels:

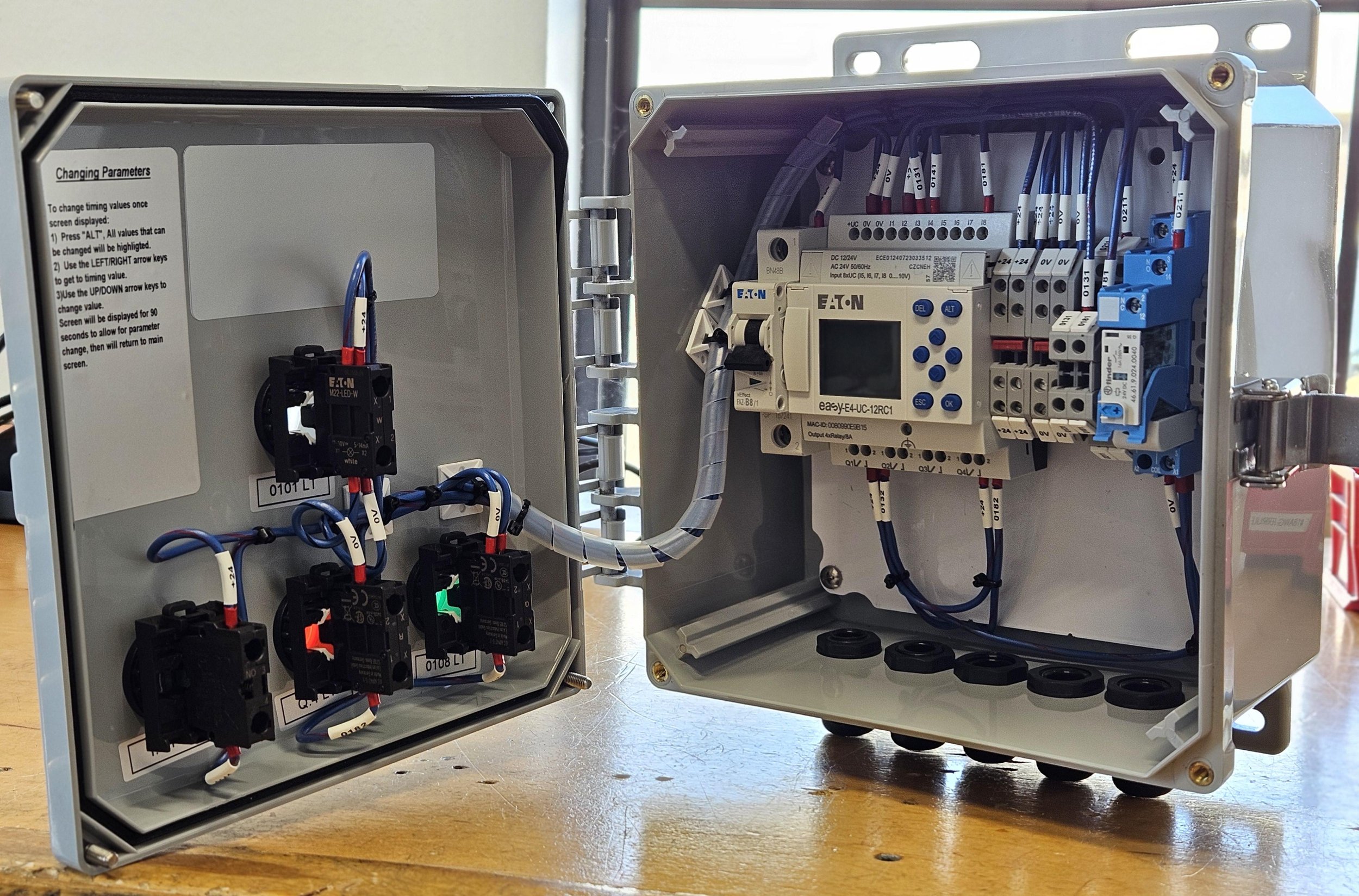

Customized Design: We work closely with clients to design control panels that integrate seamlessly with their automated lubrication systems, ensuring optimal performance in diverse applications, from heavy machinery to industrial processing lines.

Advanced Automation: Our panels support fully automated lubrication processes, reducing downtime, increasing equipment lifespan, and minimizing the risk of mechanical failure due to insufficient or excessive lubrication.

User-Friendly Interface: Equipped with intuitive touchscreens or button panels, our control systems allow easy programming and real-time monitoring, making system adjustments simple and efficient for operators.

High-Quality Components: We source only the best components for our control panels, ensuring long-term durability, resistance to harsh industrial environments, and consistent operational accuracy.

Integration Capabilities: Our control panels are designed to integrate seamlessly with existing systems, allowing for data sharing with PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems for enhanced operational oversight.

Safety and Compliance: Each panel is built to meet industry standards and regulatory requirements, ensuring the safety of both the equipment and personnel.

Cost Efficiency: With our automated control panels, customers can significantly reduce manual lubrication labor costs and improve system efficiency, contributing to a lower total cost of ownership.

Industries Served:

Manufacturing | Oil and Gas | Petro Chemical

BSA has 20+ years of experience in control panel design and manufacturing, ensuring that each system is crafted with precision and attention to detail. Whether you're looking for a solution to improve the efficiency of a large-scale industrial operation or need a specialized control system for niche applications, we can provide a customized solution that meets your specific needs. At BSA, we’re committed to delivering superior control panels that drive the performance of automated lubrication systems, helping our clients reduce downtime, boost efficiency, and protect their equipment investments. Let us help you optimize your lubrication process with our expertly engineered control panels. Contact us today to learn more about our capabilities.